In actual fact, I really noticed how grim it was all getting when jacking the car up to get the brake caliper pistons pumped out. I treated some rust forming in the arch, twigged how filthy everything was, how the wheels had started to corrode quite annoyingly despite plenty of Rimwax allegedly protecting against the winter weather...

...then I noticed stuff like this ridiculous item still being in situ...

and one thing led to another. Before you know it, half the front end's in pieces! Dirty, rusty pieces at that. And yeah, that's the bottle for the headlight washer jets. Which hadn't worked in all the time I had the car, and indeed there weren't even any jets connected since I'd swapped the Elford bumper over. Not really much use in carrying a ballast tank around then, unless you're driving a submarine. My first mission was to get rid of it, something that proved easier said than done. First thing to yield up after much penetrating fluid was...

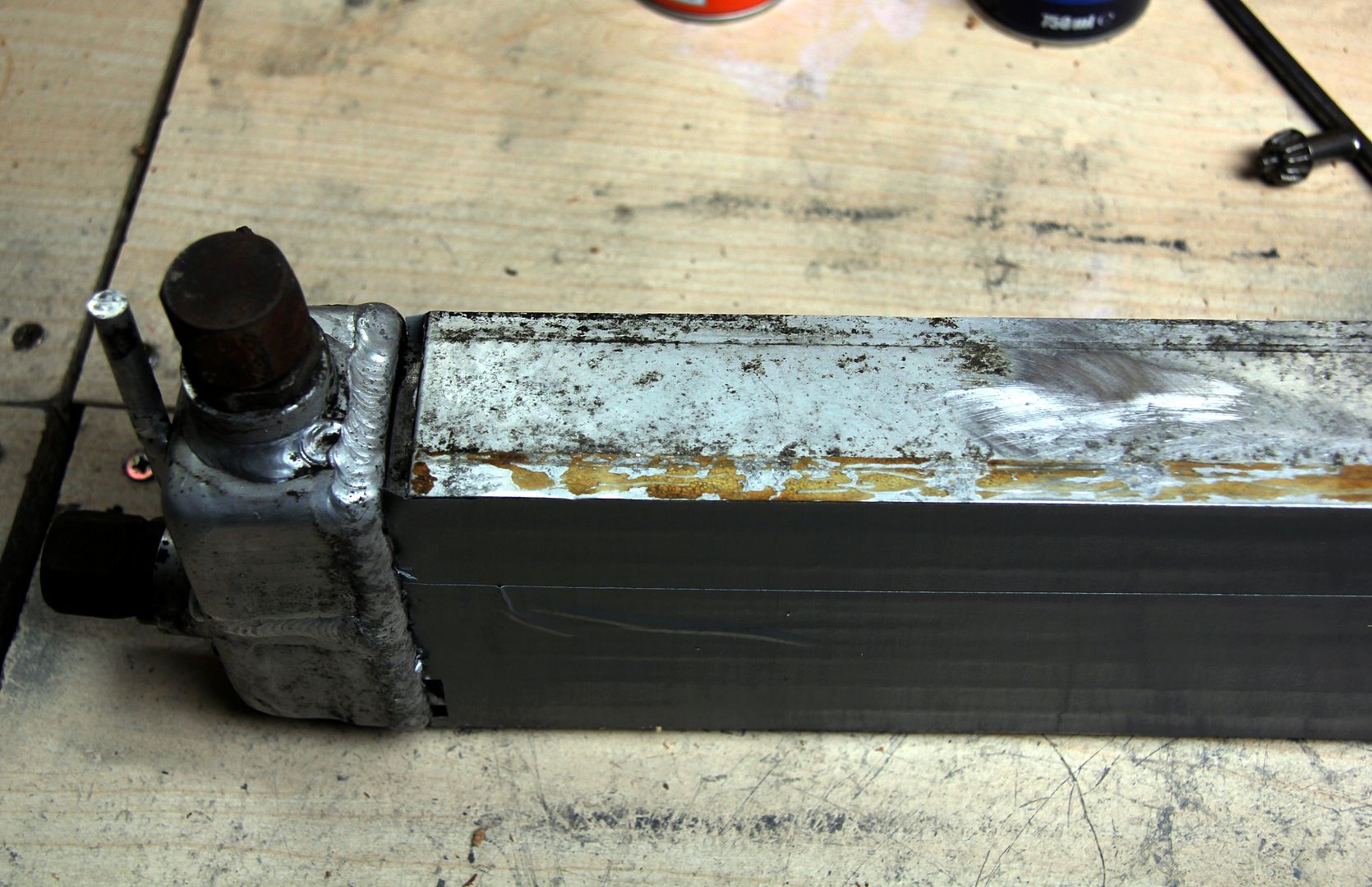

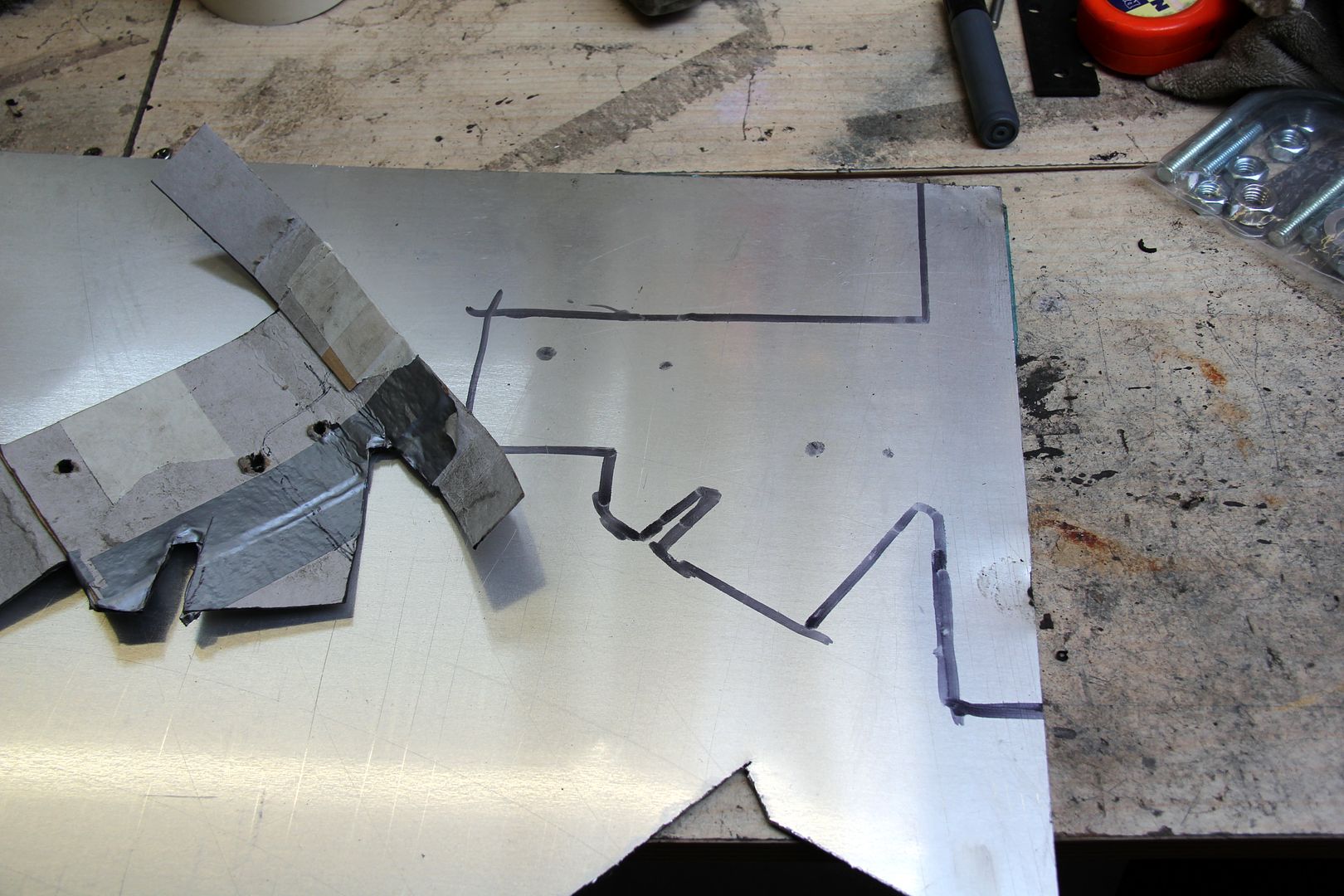

...apparently about the only brake vent deflector plate left on a UK FB, judging by my failed attempts to find another! Indeed, I don't have one the other side either. Anyway, set to work wire brushing it back and though rusty as hell there were only a couple of places it had blown right through. Looks like I saved it just in time.

How useful it actually is I'm not so sure. On the stock bumper these sit behind the little straked vents in the valance but the Elford bumper has these replaced by foglights, so there's no real airflow for the brake vents to direct. But since I've got it, I figured I might as well use it and if nothing else it'll stop some of the road slurry getting flung up inside the front of the arch. So, a couple of coats of good old fashioned lumpy Hammerite later it was ready to go back on

but first I had to divest that area of the washer reservoir. Getting the tank itself out would have been easy enough, but that would have left a big unnecessary bracket, and this was much more tricky to get gone. Mazda in their wisdom held it by a few bolts, one of which faced towards the front of the car. Maybe with the original bumper valance this is accessible but on my setup it really wasn't. In fact, without actually removing the front bumper the only way I could get to the bolt was to clip together just about every socket extension I had with a UJ in the middle and then go in through the sidelight hole! Accuracy was a bit variable with about a three-foot long socket extension with a hinge in the middle, thankfully the bolt wasn't seized or I'd have been in trouble. Eventually, after much patience and an bit of wiggling analagous to trying to fit a frozen turkey through a catflap one-handed, I was triumphant!

It was still full of stagnant water that had been there for at least the three years I'd had the car, probably a lot longer. I guess I ought to count myself lucky not to have caught Legionnaires Disease or something, lol. So I polished back the wheels as well as I could. Annoyingly, there's some pitting to the polished rims but they came up well enough with a lot of Autosol. To get them any better I'm going to have to bite the bullet and get in there with the wet and dry and some mopping, which I just didn't have the time or inclination for just now. Irritating, but I should have known better that just cos a manufacturer claims them to be all-weather doesn't mean it's true

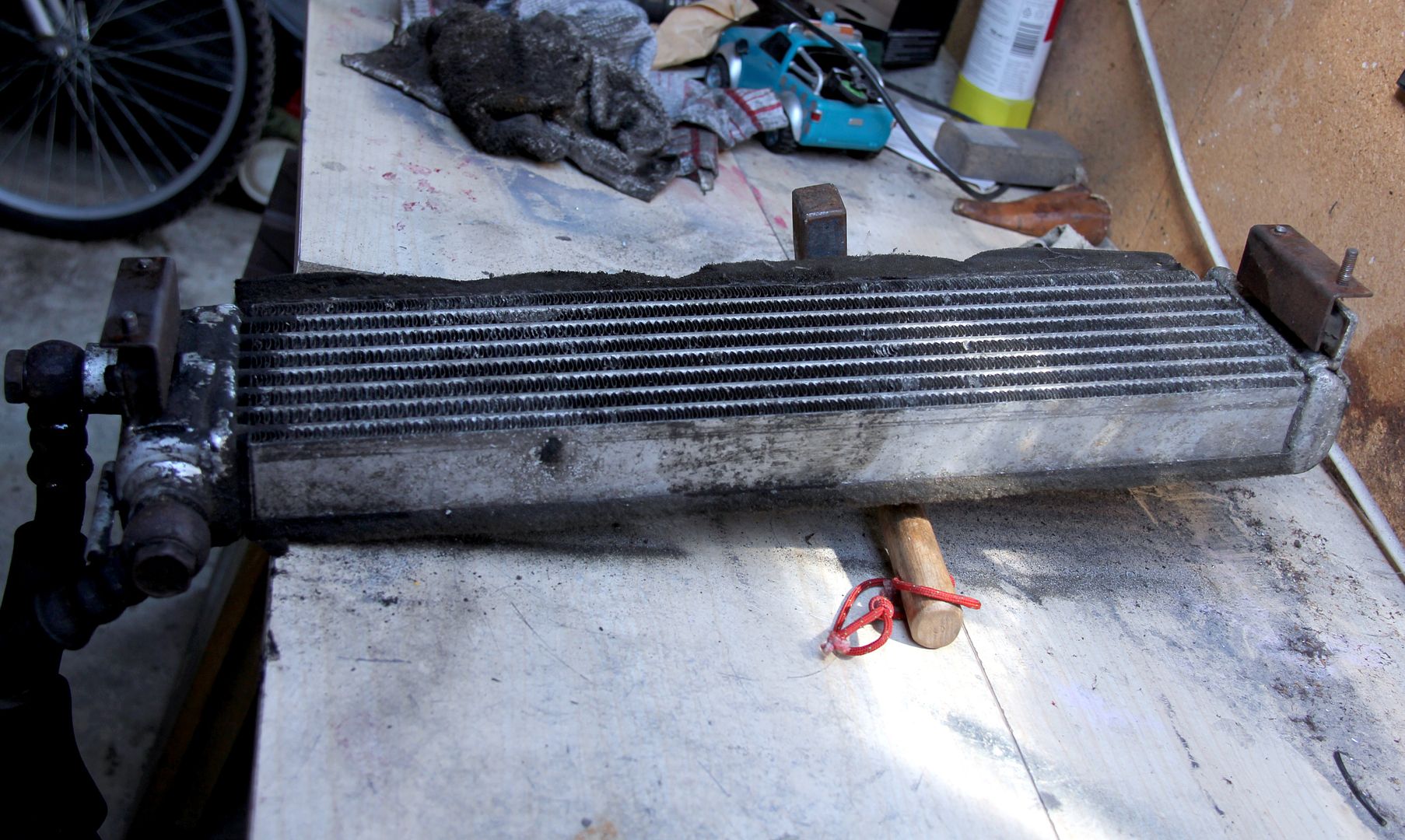

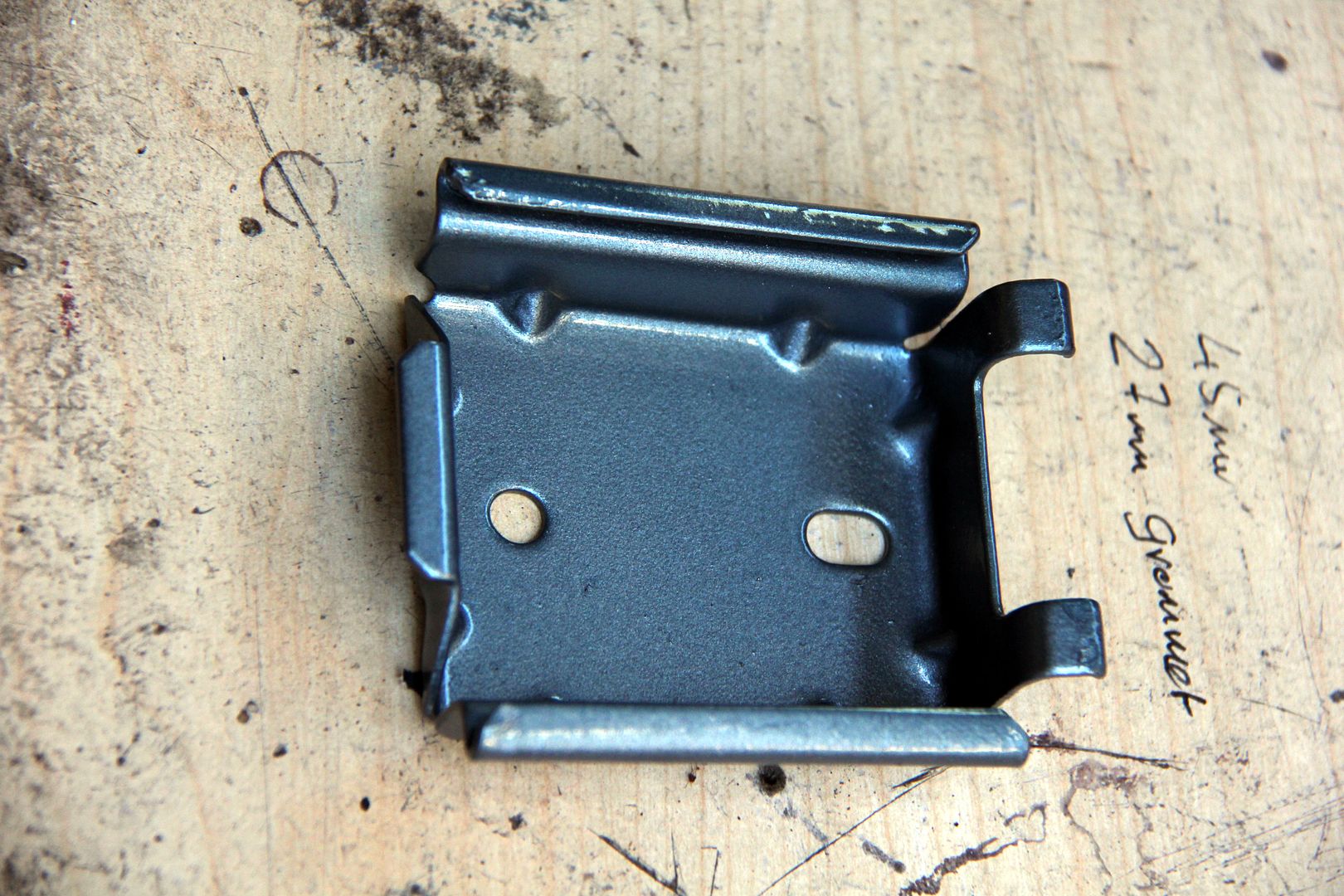

So now I could get on with what I wanted to in the first place; tidying up the bay a bit. Simple enough to strip down the radiator shroud panels, though you need some other method of supporting the radiator while they're off (I used bungees, lol). So I ended up with these disreputable items;

and the little bracket that the expansion bottle clips into. I have to say, I love the easy way the bottle just slides into detent on this bracket, it's a nice touch and makes me wonder why all the tanks on an FD are such an occult pain in the arse to get to and remove

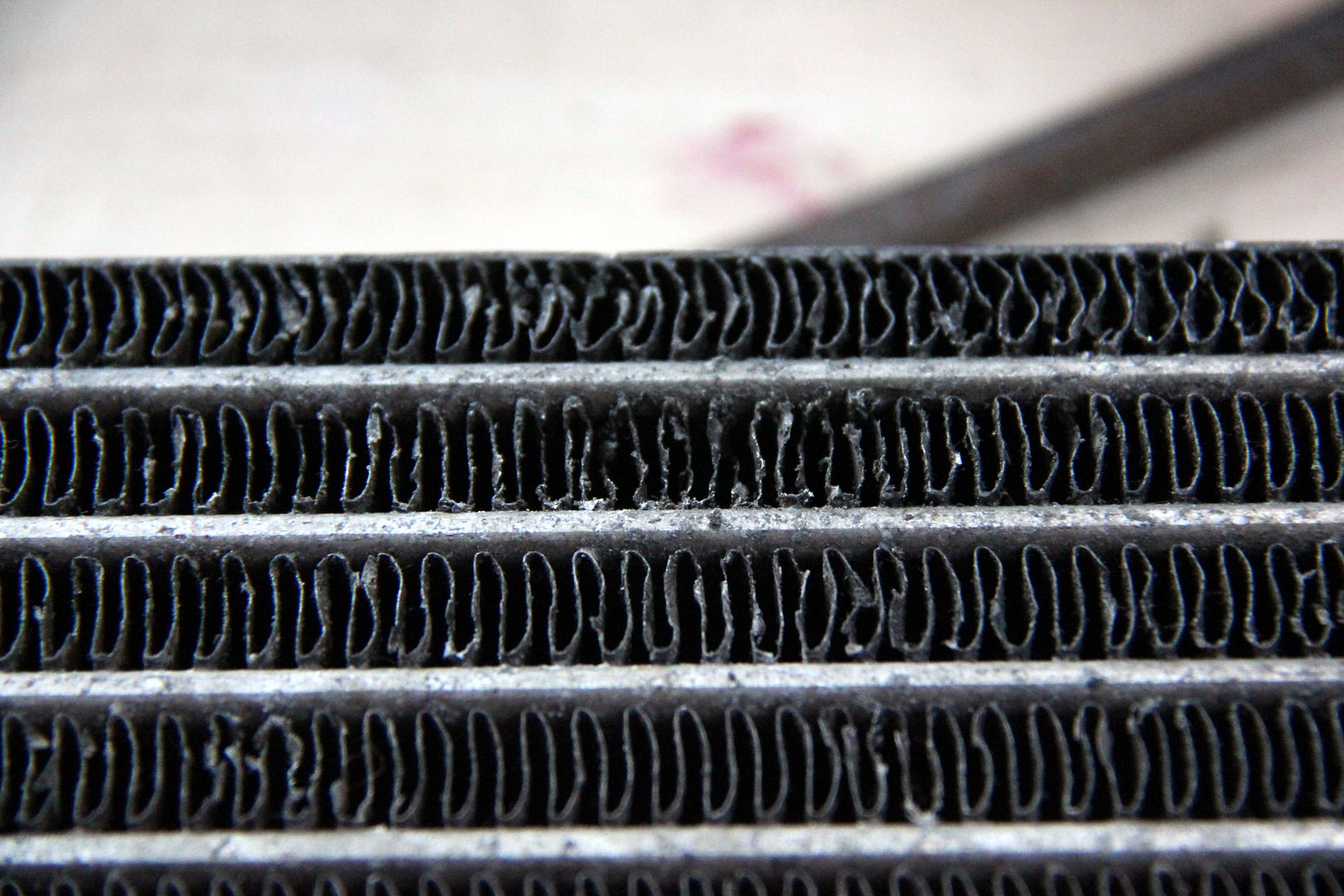

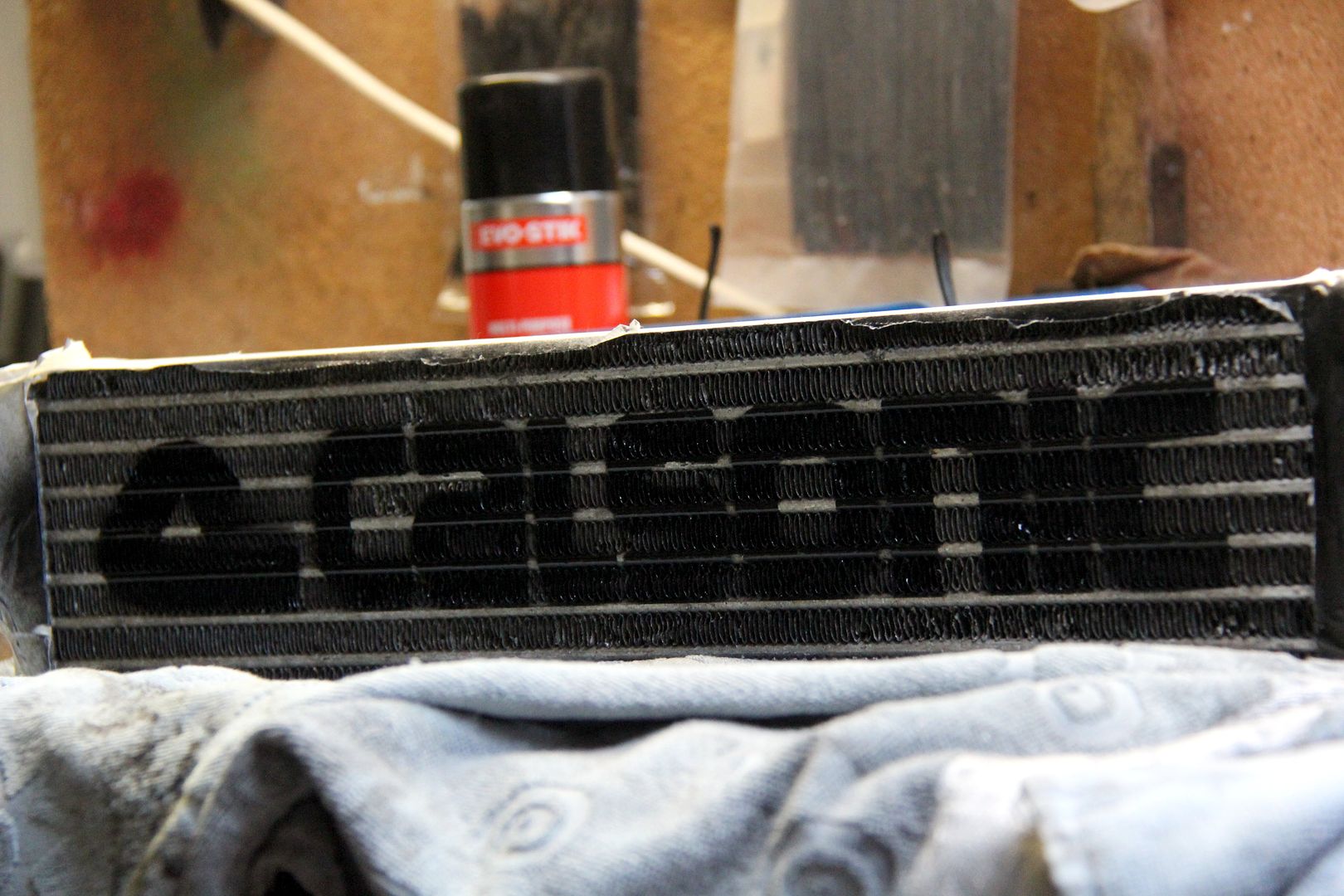

So these were wire brushed back

and treated with rust convertor... and one thing I've found over the years is that all rust convertors are not created equal. Kurust might have been bought out by Hammerite, but in fairness they know a thing or too about rust treatment anyway, and the original Kurust for me is still the best. For a start, it actually stays where you put it... cheap brands tend to be too thin and run off the place you want them to stick and work on. Also, I find you can sand it back without it disappearing completely and it seems a more permanent solution in as much as it stops rust coming back

I painted the radiator cowling with spray Hammerite because I want it to stay black, not turn back into rust as soon as it rains. I know many people hate the stuff, but I don't mind it; it serves a purpose, and it gives a much better finish nowadays than back when

The expansion tank bracket I painted body colour. Not really sure why, just because I could, I suppose. It had originally been just galvanised without paint at all. The paint I actually got from Halfrauds. Yeah, they are good for something! Just give them the paint code and for twelve quid you get a colour-matched rattle can. It's not a perfect match, I mean I wouldn't try to blend in a wing using it, but for brackets in the bay and such it's fine. In fact, my paint isn't a factory colour match any more anyway; when Jason sprayed the bodykit the paint code came nowhere near matching as years of exposure had taken their toll, so we ended up mixing an almost bespoke colour somewhere near Tender Blue but not quite. It's quite possible the Halfords one is how mine would have looked 28 years ago

While the radiator ducting was all apart I took the opportunity to fit a pair of decent horns to replace the whisper-quiet and tired originals. I made up a mini-loom for them, which gave me a chance to renew my long dormant soldering and connector crimping skills. I actually bought a proper OE-quality connector crimp tool a while back but this was the first chance I'd had to play with it.

And it was probably just as well I was messing around with wiring because it led me to discover perhaps the reason I'd been experiencing a few electrical gremlins. A couple of times the car struggled to start and the battery seemed to not hold a charge as well as you'd expect, despite the voltmeter showing good charge. Think this may have been the culprit;

Guess that's what 29 years of over-tightening a battery clamp will do. Someone had added in a spacer at some point, and it had just chewed right through the metal over time! Annoyingly, the only way to get the knackered clamp off the cable was to cut it and then the cable was just too short to reach the battery terminal with the new clamp. So I had to cut the cable off the union below the fusible links and run a new length with a new clamp. Still, it gave me the chance to replace it with a bigger gauge wire so hopefully that'll work better than ever. While I was messing around down there with cables I replaced the nasty plastic clips on the HT wires with some nice alloy ones, as discovered over the Pond by Jesse

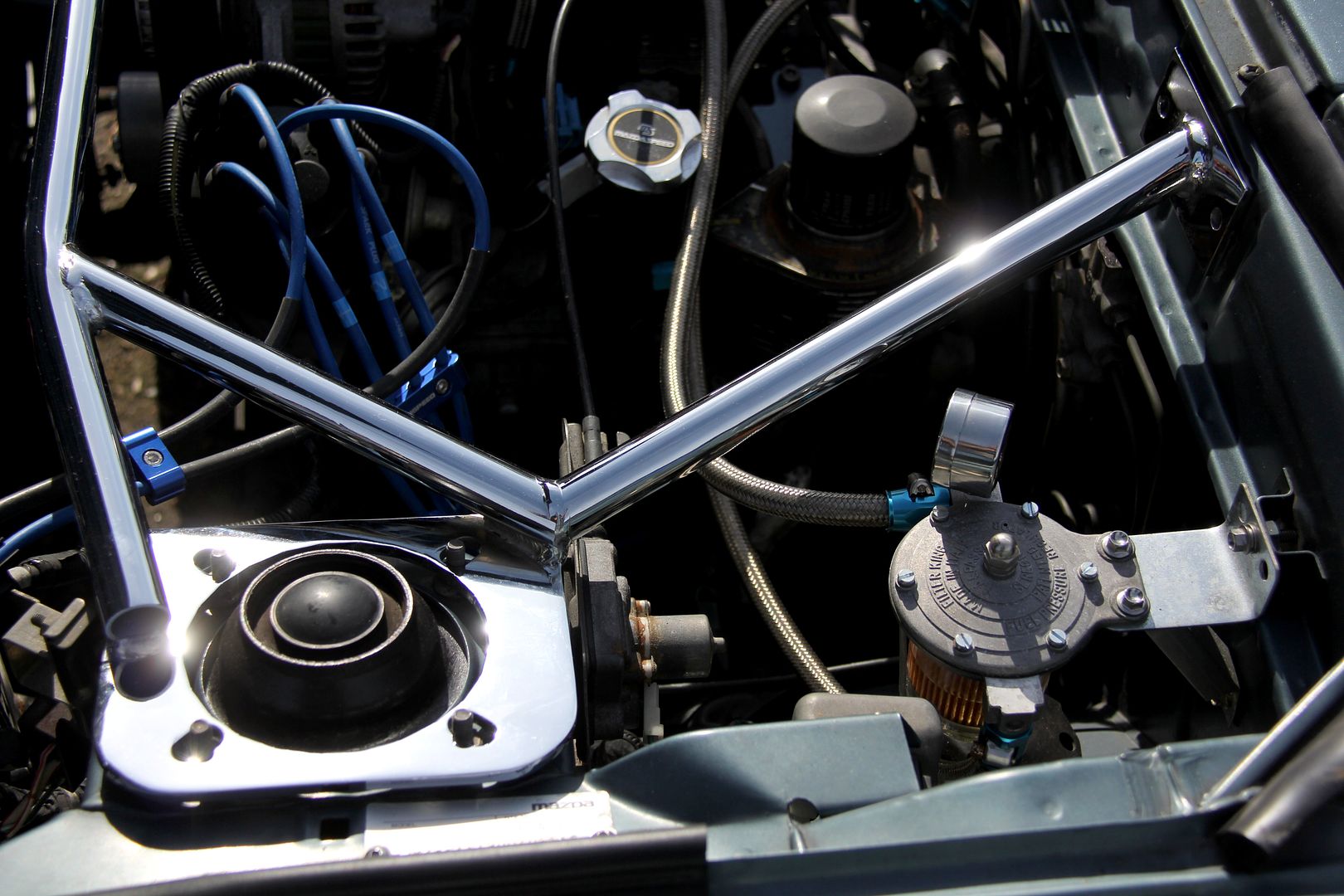

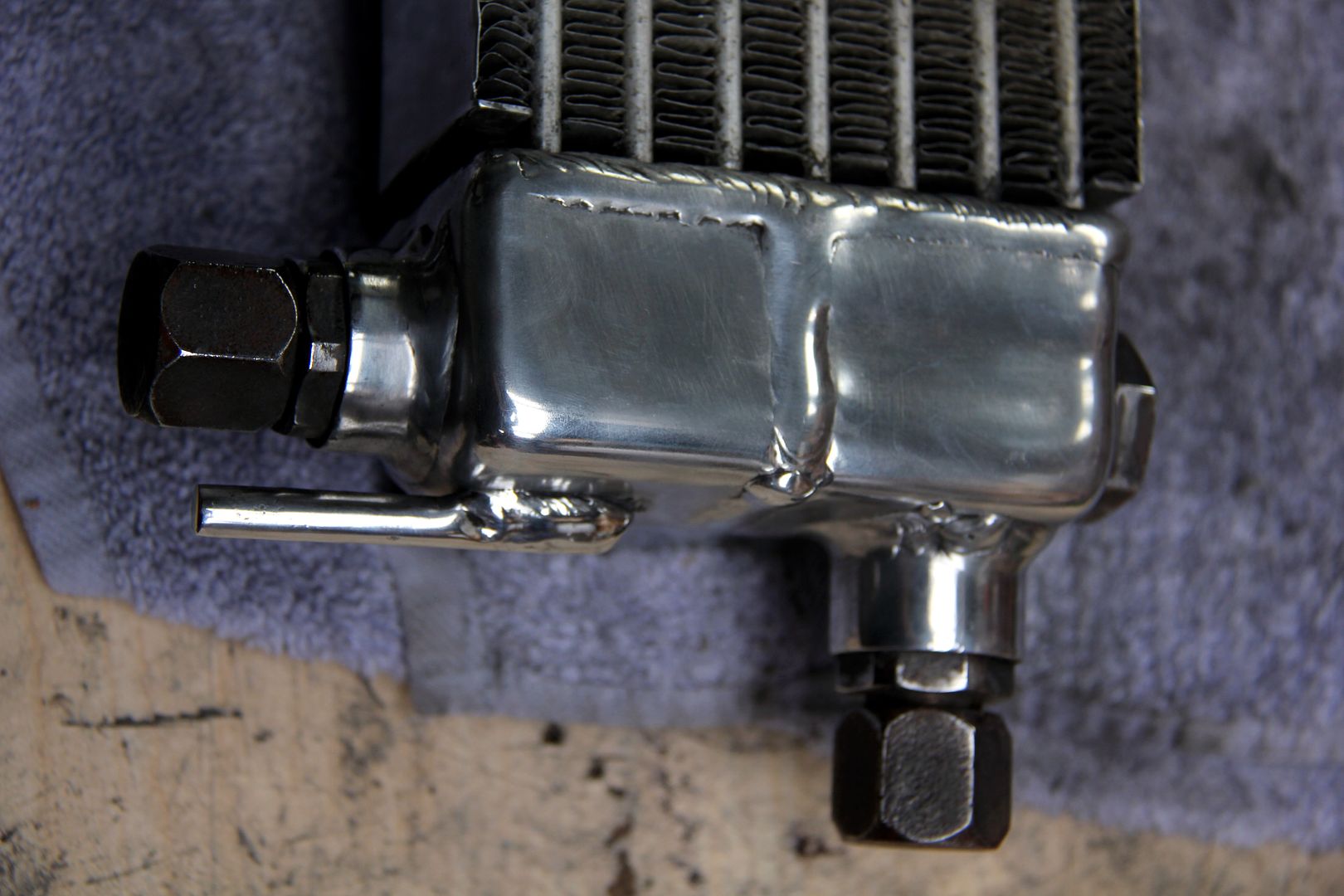

So the re-assembly could now begin, Stainless fasteners throughout, of course!

I also found time to make a new home for the VIN plate, which was dislodged from its original place on the firewall because it was right where the buttress plate on the strut brace went. I originally intended to put in some rivnuts here, but handily the thickness of steel was enough that I could just tap a thread directly into the top of the turret plate. Which is good, cos it meant an M4 hole instead of a gurt big one that might compromise structurally strength rather more!

So here it all is going back together. I put blanking grommets in where the holes for the washer pump wiring and that had been, though there's not much you can do about the big hole where the filler neck used to go

and of course this was another opportunity to feed my braided steel hose fetish, so I replaced the unlovely rubber overflow pipe with some nice braided

and spent a few extra hours swapping out every rusty bolt I could easily get to with stainless, such as here on the fuel pressure reg, which I can't remember if I posted pics of before. But anyway, here it is, and the bolts had rusted already (seems the Italians are still using the same quality of steel on their automotive products that Mazda were three decades ago!). Much of this wiring will be tidied up as part of the engine swap, including I guess losing the little throttle-blipping starter robot. Which is actually a bit sad, really, lol. I wanted to move onto the nearside of the bay and the other radiator shroud, which meant taking the battery out and all that, but I ran out of time.

On days when the weather meant I didn't want to be outside or under the bonnet, I plodded on with a few other jobs. I finally found a company offering alloy intake trumpets for Webers... Weber only offer plated steel, which looks utterly cack and very few companies in the aftermarket seem to make them in alloy for 48IDAs. So, the alloy ones I eventually found were an improvement but could be better still

I think because they're spun they have little striations all around the circumference, which meant whilst they were nicer than the steel, they weren't exactly what you'd call shiny. So I got busy with the masking tape to protect the mounting flange from damage...

... and started sanding back. It's always a bit dis-heartening taking something halfway decently finished and making it look crap, but it'll pay off in the long run

At least these are small, flat (or at least mostly single-planar) so it didn't take long to work up through 120, 240, 400, 800 and finally to 1200 grit sandpaper. This is at the point of a final sand with 2000 grit before polishing... the one on the right, obviously, lol. Un-sanded one included for contrast

Annoyingly, my bench grinder blew up mid-way through polishing the vast expanse of a mates' straight-six Opel Commodore rocker box so I had to do the final polishing with a drill and arbor mount, so the fini9sh wasn't quite a s good as I'd have liked. If Frosts ever get round to delivering the replacement grinder I ordered I might give them another whizz over. However, they're certainly shinier than they were;

...especially when compared against the eezzee-scratch steel original Weber ones!

Here my work is being subjected to the Conrad Quality Scrutiny Test. Seems to have passed. Of course, these will mostly be hidden by the tea-strainer airfilters, but that's not the point. I'll know they're there and the inch or so that shows will be shiny as hell, lol. Don't I always say it's all about the details...